Sometimes, rooms within a building require both a high level of fire and blast protection and complete freedom of access. Areas such as equipment rooms and indoor substations can need machinery to be removed entirely, so that it can be properly assessed, maintained or replaced. With a traditional fire and blast protection material such as concrete, this often requires the whole system to be demolished.

Demountable fire barriers allow rooms to be created that fulfil both of these criteria. Durasteel barriers provide up to 240 minute fire protection and comprehensive blast resistance, while also being easy to demount and remove when required. This both reduces the long-term costs of protecting the room, and the cost and disruption of accessing the room for scheduled or unscheduled maintenance.

As well as resisting even extreme hydrocarbon fires and limiting noise up to 56dB, our demountable panel fire barrier systems can be quickly and easily removed, either as prefabricated modules or piece-by-piece. The modular design leaves a completely unobstructed and flush-finish opening in the system, through which equipment and personnel can be freely transported.

This removal process can be completed entirely by hand, and does not require the use of any specialist lifting equipment. For areas such as metro tunnels that are subject to extreme changes in air pressures or frequent vibration, the barriers can also be engineered to resist these pressures and the long-term effects of cyclic loading.

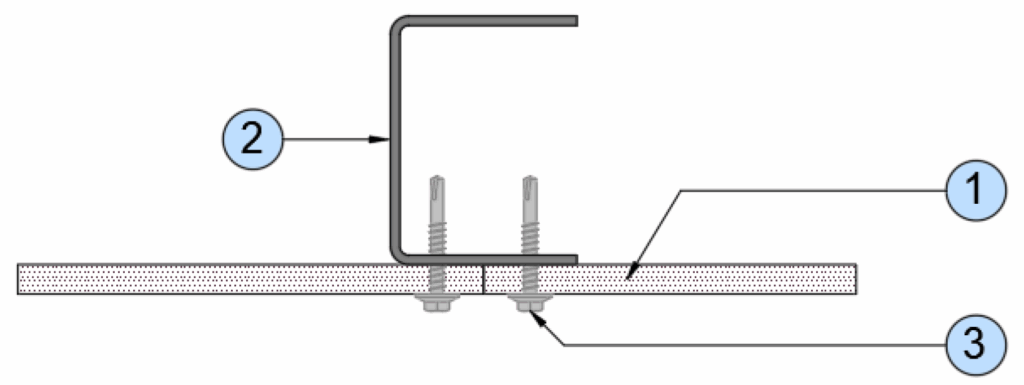

Services that are required to pass laterally through the barrier can be separately framed out in a non-demountable section, and firestopped using our certified penetration seals. If regular personnel access into the room is required, a Durasteel door can also be built into the demountable barrier.

For an example of how demountable barriers can be easily removed from challenging environments, check out our ADNOC M project, where 15 barriers were installed in the world’s largest underground oil facility. Alternatively, get in touch with us today to discuss your unique requirements, and start your demountable barrier project.

UK

UK

US

US

UAE

UAE

Qatar

Qatar

India

India

Malaysia

Malaysia